The boyfriend and I (more accurately the boyfriend, since he did most of the paying) acquired a van for the purposes of windsurfing. We wanted something to carry all the kit, get changed in when it was particularly horrid outside and even something to sleep in over a windy weekend. While we were at it, we thought we might as well go the whole way and do enough work on the interior to get it reclassified as a motorhome (they are a bit cheaper to insure than commercial panel vans, and can be driven at higher speeds). So... here's the picture book story:

This is what we started with: a blue, LWB Renault Trafic, complete with magic numberplate. It still doesn't quite fit in my parking space. Oh well.

The first job was getting a side window put in. We had this done professionally as our DIY skills were nil before we started this, and taking a saw/other massive cutting implement to the side of the van was a bit too daunting!

The second job was removing the bulkhead. It was mostly held in with simple torx bolts, except for two weird blind-head thingies. These had to be pyoinged off with a hammer and screwdriver. Here's the man in action, or doing his best Blair Witch man-in-the-corner impression.

After that, we cleaned out the interior and made sure to cover any scratches/bare metal with primer and paint. Though we didn't want any of the shell to get wet from all the windy gear, there was/is always the chance of a leakage through whatever protective layers we install, so we thought a bit of rust protection at this stage was a good idea.

We put down some battens using a combination of bolts and flexi-glue. The ply lining would later be anchored to these battens and the van skeleton. Some of the insulation has already been glued to the ceiling here:

Ply-ing the ceiling could start, and the light holes could be put in. We decided to go for LED recessed lights - they use very little power and don't get too hot, so hopefully won't set fire to the carpeting that'll be added later.

This is what we started with: a blue, LWB Renault Trafic, complete with magic numberplate. It still doesn't quite fit in my parking space. Oh well.

The first job was getting a side window put in. We had this done professionally as our DIY skills were nil before we started this, and taking a saw/other massive cutting implement to the side of the van was a bit too daunting!

The second job was removing the bulkhead. It was mostly held in with simple torx bolts, except for two weird blind-head thingies. These had to be pyoinged off with a hammer and screwdriver. Here's the man in action, or doing his best Blair Witch man-in-the-corner impression.

Free!

After that, we cleaned out the interior and made sure to cover any scratches/bare metal with primer and paint. Though we didn't want any of the shell to get wet from all the windy gear, there was/is always the chance of a leakage through whatever protective layers we install, so we thought a bit of rust protection at this stage was a good idea.

Next, we added some sound-deadening sheets to the panels in the hope of dulling the chassis vibrations.

We probably could have added more sound-dead stuff, but we drove it around and it was already pretty quiet, so we left it at this...

As you can see, we employed stringent safety measures in order to protect eyes and lungs. This is very important when cutting down pieces of Celotex(tm) insulation.

For some of the build, I took up this position and 'protected the manly tools'

We put down some battens using a combination of bolts and flexi-glue. The ply lining would later be anchored to these battens and the van skeleton. Some of the insulation has already been glued to the ceiling here:

Then came more insulation...

We plumped for the plastic, recycled-bottle stuff. It's supposed to be good at not retaining water. However, it also seemed to be out of stock at all branches of B&Q, so we lined most of the van before running out in one corner. That bit had to be left unfinished for a while :(

Anyway, the floor battens went in next, complete with bits of insulation and the first layer of ply on top. We'd worked out at this point that space (especially vertically) was going to be really tight with our plan, so we kept the floor layer relatively thin.

More insulation on the back doors...

Next came the ply lining and the first bits of wiring.

The first bits of wood for what would become the bench.... The van stayed in this state while we took it down to Wales for a bit...

When we got back it was time to build some more! Here the basic frame of the bench has been built, and a load of kit has been inserted under it to check if it will all fit - two boards, three sails and two booms to start with...

More bench:

This is all Tim's creation - the bed will pull out like this when it's done:

Ply-ing the ceiling could start, and the light holes could be put in. We decided to go for LED recessed lights - they use very little power and don't get too hot, so hopefully won't set fire to the carpeting that'll be added later.

Finally, the extra insulation arrived, and the other side of the van could be lined. A retaining wall for the windy kit was also added. There was a lot of glue holding various bits in place where screws weren't possible (note props)!

The kit area needed to be waterproofed fairly early on as we were using the van for outings even as it was a work-in-progress. In went some vinyl...

More of the kit area was waterproofed - we now have three boards (two fs, one w), seven sails, two booms in there:

Next, some MDF was wrapped around the curvy bit of the bench, some vinyl put on the floor and the rear sections constructed.

Then came the upholstery and some wood veneer added to the front of the MDF. We waterproofed it using some 'special' oil. Actually, it's more splash-proof than anything else, since water could still potentially get underneath it and soak upwards. Should be enough to withstand us getting changed out of wetsuits all over it though. There were also more bits built at the rear. Unfortunately, I didn't take many more pictures of this stage, which would have shown Tim's ingenious board-insertion system. More about that later...

More upholstery...

And more...

I made a fin storage system for one of the rear doors...

This is how the rear looked. We have a water and waste tank under the sink/hob on the left, and the waterproof kit zone on the right.

The lights had been dangling and swinging around and hitting stuff for too long by this stage... it was finally time to carpet the ceiling and install them!

This is the hob area. There's a cupboard underneath for plates and that sort of stuff. We put a bit of formica on the top and sealed everything in. The grey flat stuff around is vinyl (wipe clean!) so we'll have to wait and see how that holds up, but I thought it might fare better than steamed, pan-spit-fat carpet.

More carpeting...

And more carpeting! This is how it looks with the bed pulled out:

Lights on...

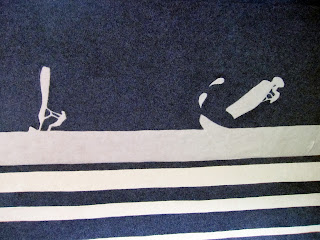

I made windy carpet art!

Then came many hours of messing around with silicone sealant and skirting board. There's a compressor cool box in the corner and an electrics cupboard behind that. The leisure battery is hiding under the passenger seat.

Hob and sink...

Kitchen zone :)

Deep in the electrics cupboard:

This is what happens if you press the PARTY button:

This is the rear, complete with a spongy bit to separate wet zone from dry!

And with tanks:

This is Tim's board insertion system in action! Because the wave board that has to fit down here is bendy (but not quite bendy enough), it's tricky to get it lying along the side of the van when the chassis door frame (and our wooden structure) is in the way. Soooo a couple of side doors open up to give greater access to the side portion of the wet zone and allow for the correct angle of entry. Fnarr.

Then there's the second wave board, which lives at the top. To get to this, we have two flaps that open downwards, comme ca:

Going in:

And here's the rear, full of EVERYTHING (okay, we took the gas cannister out, we didn't need it for this particular trip)! In here we have....

two wetsuits

two harnesses

two booms

four masts

seven sails

two freestyle boards

two wave boards

eight fins

three extensions

two mast feet

four wetsuit boots

various screwdrivers and other miscellany

Ready for (just about) anything :)

Oh, and here's the cupboard for all of the kitchen-y stuff.

There's still the table to attach before we can get the van reclassified, but that'll happen sooooon!

MOAR IMAJS:

No comments:

Post a Comment